On the Sentec Transcutaneous Monitoring System, Sensor Problem 12 is commonly caused by a defective membrane or dried electrolyte.

You can watch the tutorial video or follow the step-by-step instructions below to learn how to troubleshoot this error message.

Step-by-step instructions for troubleshooting

✔If the center ring is brown and intact, continue to the next step to perform a clean and soak on the sensor.

✔If the center ring has a white or silver luster, the sensor may be defective. Contact the Sentec Service Team at for further support.

✔Disconnect the sensor from the sensor adapter cable.

✔Remove the current membrane from the sensor using the bottom of the membrane changer. If the membrane does not come off easily, you can first soak the sensor in clean water with the membrane on.

✔Once the membrane is removed, immerse the sensor in clean room temperature water for up to 3 minutes.

✔After soaking, gently rinse the sensor with clean water.

✔Dry the grooves around the sensor with clean, lint-free gauze, making sure there is no gel residue remaining. To dry the sensor surface, gently tap with gauze. (Do not wipe or rub the sensor surface, as this can cause damage.)

TIP! Ensure the sensor surface is not damaged by sharp-edged objects or fingernails during this process. Damage to the sensor can cause incorrect measurements.

For more information on performing this process, visit our clean and soak tutorial.

✔Turn the sensor face upwards and carefully insert it into the Sentec Membrane Changer, being careful not to touch the exposed sensor surface and ensuring the sensor is aligned correctly. Then, proceed with the membrane change as usual.

For more information on using the Sentec Membrane Changer, visit our step-by-step tutorial video.

✔After the membrane change is complete, ensure there are no air bubbles and/or wrinkles between the sensor and membrane and verify that the membrane is correctly situated on the sensor.

✔Reconnect the sensor and confirm the membrane change by opening the docking station door and selecting ‘Membrane Change Done.’

✔Immediately start a sensitivity test once the membrane change is confirmed. This is required to clear the error message.

✔To run a sensitivity test, select the ‘Menu’ button (top left) and choose ‘Measurement Settings’. Then, select ‘PCO2 Settings’ and choose ‘Sensitivity Test.’

✔Upon the monitor’s prompt, open the docking station door. The status bar will show ‘Sensitivity Test.” After 2 minutes, you’ll receive a prompt and an audible beep signaling you to close the door, which will initiate the sensitivity test. The phrase, „Leak test in progress,“ will appear on the screen. Expect the test to conclude within approximately 15 minutes.

✔If the screen displays ‚Ready for use‘ after the test, the Sensor Problem 12 error has been successfully resolved.

TIP! In order to clear a Sensor Problem 12 error, the sensitivity test must be completed successfully. If the monitor continues to display the error message during the Leak test portion of the sensitivity test, check the docking station gasket. Ensure the gasket is installed with the bevel side facing outwards, and also that the gasket is free of any debris.

For additional support on resolving a gas leak in the docking station, visit our troubleshooting page here.

✔Should your monitor continue displaying the ‚Sensor Problem 12‘ error message after completing these steps, please reach out to the Sentec Service Team for additional troubleshooting support.

For more troubleshooting information, see our Service Manual.

Product Support Webinars

For more product support resources, browse our collection of on-demand webinars led by our team of product and clinical specialists. Gain valuable insights on proactive maintenance, troubleshooting, and optimizing the use of your Sentec Transcutaneous Monitoring System.

Transkutanes Monitoring auf der NICU: Praktische Anwendungen, Leitlinien und Überlegungen

Erörterung der CO2-Ziele bei Neugeborenen, und wie transkutanes Monitoring einen kontinuierlichen Blick auf die Veränderungen des CO2-Status des Patienten ermöglichen kann.

Proaktive respiratorische Versorgung mit transkutanem CO2-Monitoring auf der PICU

Aufklärung über den klinischen Mehrwert einer genauen, kontinuierlichen, nicht-invasiven CO2-Überwachung für das Beatmungsmanagement auf der PICU.

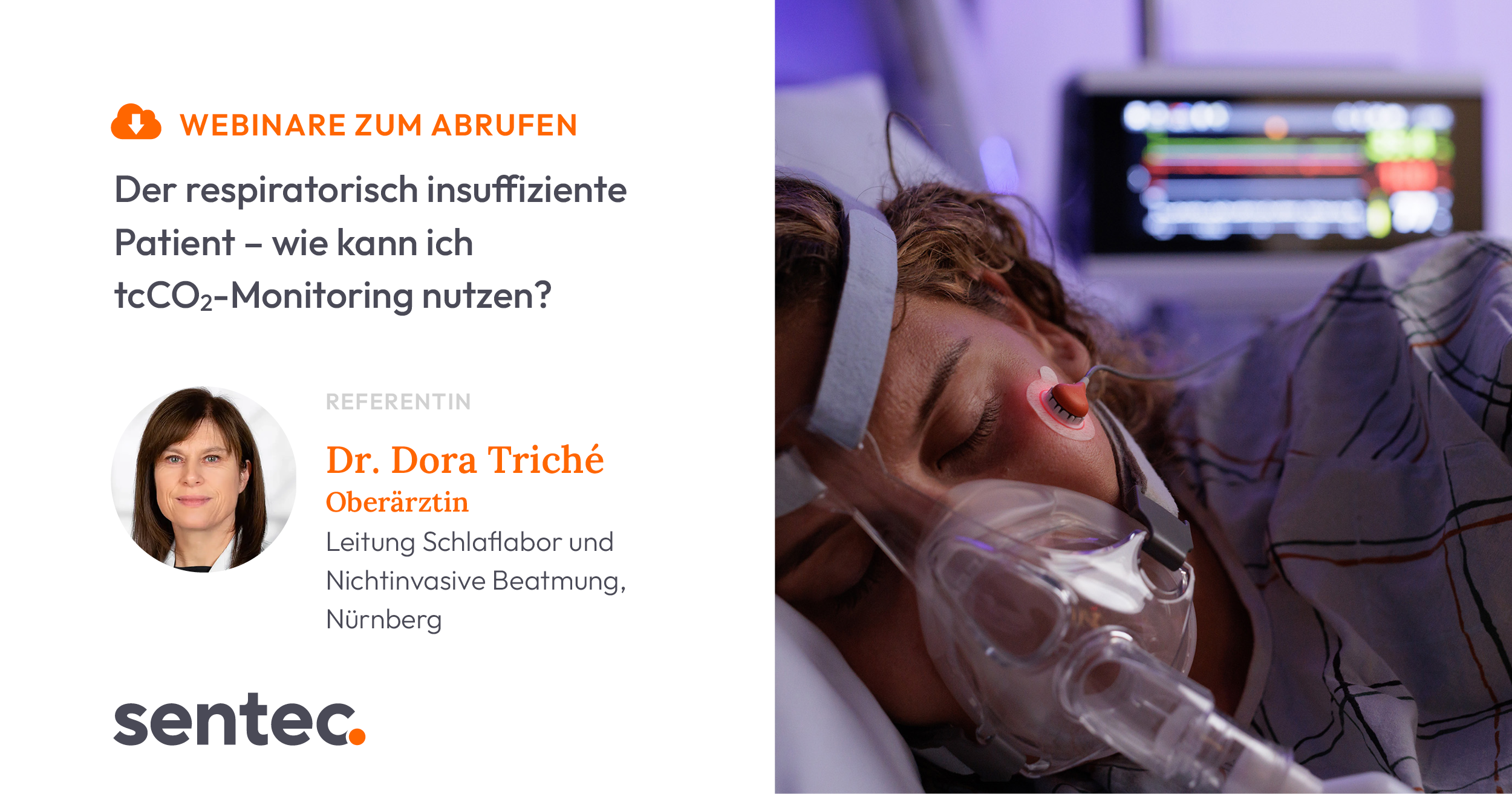

Der respiratorisch insuffiziente Patient – wie kann ich tcCO2-Monitoring nutzen?

Erkennung der respiratorischen Insuffizienz Typ 2: Bei welchen Patienten muss ich daran denken, welche diagnostischen Schritte sind notwendig?

Still have questions?

Complete this form to for additional product support. After you’ve submitted your query, the appropriate Sentec associate will reach out with more information.

Related Posts

Fehlerbehebung und Verbesserung der Sensorleistung

Fehlermeldungen auf dem Monitor zu beheben, einschliesslich den Sensorproblemen (SP) 10, 11, 12 und 15 und Gasleck in der Docking Station.

- Trainingsmodul

tCOM+ e-learning modules

Explore our collection of e-learning modules for using the tCOM+

Korrelation und Relative Heizleistung

Die mit dem Transkutanen Monitoring System von Sentec (SDMS) ermittelten tcPCO2-Messwerte sind üblicherweise sehr genau. Es kann aber Situationen geben, in denen die Korrelation mit arteriell ermittelten Messwerten schwierig ist oder in denen die transkutanen Messwerte den Zustand des Patienten nicht korrekt wiederzugeben scheinen.